| Item | Description |

|---|---|

| Model | In-Ear Monitor Earphones |

| Driver Configuration | 14.2mm planar magnetic IEM |

| 16Ω | |

| Frequency Response Range | 20Hz – 20kHz |

| Sensitivity | 109dB/mW @1kHz |

| Total Harmonic Distortion (THD) | < 0.2% @1kHz |

| Type | In-Ear |

| Plug Diameter | 3.5mm / 4.4mm/Type C |

| Cable Type | 8-core silver-plated wire |

| Cable Connector | Detachable 0.78mm 2-pin or MMCX |

| Cable Length | Approx. 120cm (customizable) |

| Earphone Material | CNC metal |

🎧 Planar Magnetic Technology

Unlike traditional dynamic or BA drivers, planar magnetic drivers use a large ultra-thin diaphragm suspended between dual magnetic arrays. The entire surface moves uniformly, delivering cleaner, faster, and more accurate sound reproduction.

⚡ Ultra-Fast Transient Response

Planar diaphragms react instantly to audio signals, revealing micro-details, textures, and transients that ordinary drivers often miss. Perfect for HiFi listening and studio-grade accuracy.

🌌 Wide & Natural Soundstage

The even movement of the diaphragm creates a more open, spacious sound field. Instruments feel more separated, airy, and lifelike—ideal for premium audiophile tuning.

🎼 Low Distortion & High Resolution

Because the whole diaphragm moves evenly rather than from a single point, distortion is significantly reduced. The result is a smooth, controlled, high-resolution signature that stays consistent at all volumes.

🎨 Fully Customizable Design

Choose your own shell shape, color, faceplate material, cable, tuning style, and logo application. Tailored for audio brands, musicians, and OEM/ODM projects looking for a flagship-level custom model.

🏆 Recommended for Premium HiFi Brands

With its clean detail retrieval, wide stage, and ultra-low distortion, this custom planar magnetic IEM is ideal for building a hero product, elevating brand image, or offering a premium upgrade in your earphone lineup.

With the rapid development of science and technology, people are becoming more and more sensitive to audio, and the requirements for the manufacturer of headphones are also increasing.

Digcue is a comprehensive enterprise integrated with the design, R&D, manufacture and sales of earphones, audio products and mobile accessories, provides customized headset services, including custom wired headsets, custom Bluetooth headsets, custom bone conduction headsets, custom true wireless stereo earbuds, custom active noise reduction headsets and other services.

Digcue’s advanced equipment and years of professional knowledge make us become one of the most advantageous headset manufacturers in the world.

Customized content:

Full Product Customization: Structure, electronics, software, and acoustic design tailored according to the customer’s provided ID or specifications.

Color & Appearance Options: Multiple color schemes and unique designs to match your brand identity.

Logo Personalization: Custom logo printing or engraving on earphones and accessories.

Packaging Design: Tailored packaging solutions to enhance brand presence and create a memorable unboxing experience.

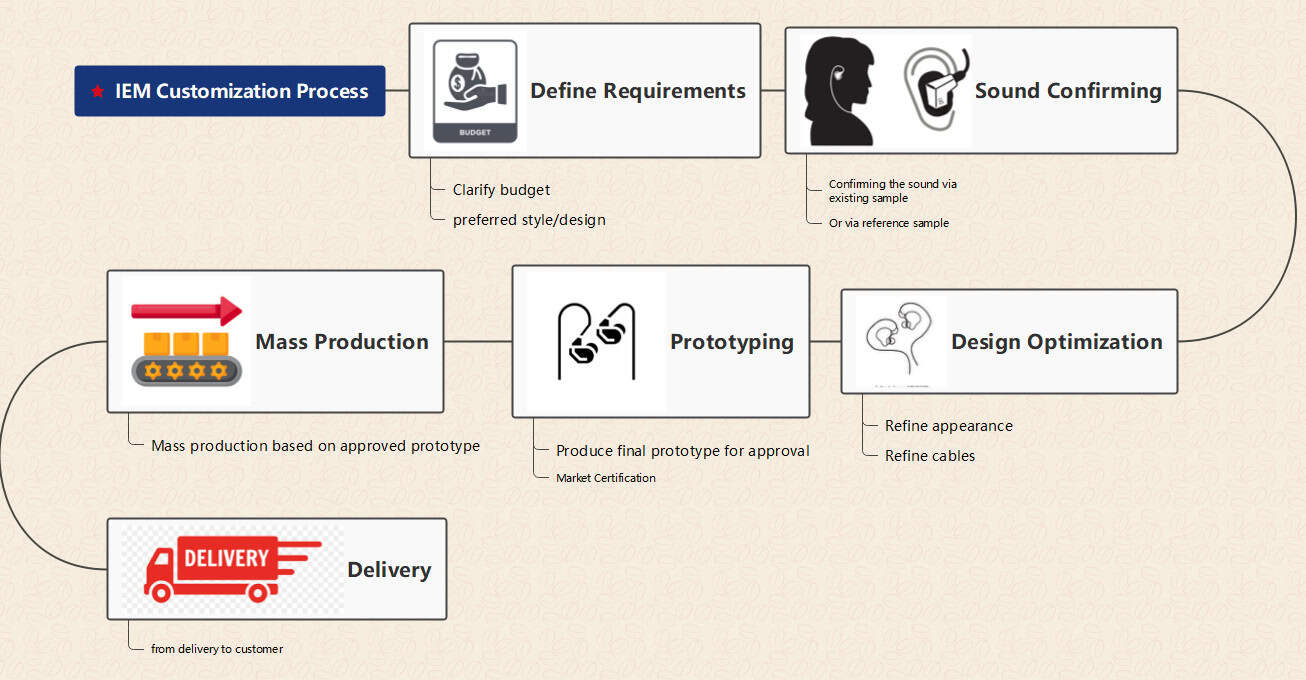

Custom Headphone Assembly Process

ID design >> structural design / acoustic design / PCBA design-engineering prototype >> sound debugging >> earphone mold >> secondary sound debugging >> trial production >> mass production.

Custom Packaging Tailored to Your Brand

Enhance your brand presence with personalized packaging solutions that tell your story and embody your identity.

From high-quality materials to creative designs, we craft packaging that not only protects your product but creates a memorable unboxing experience that captivates and delights your customers.

Certification Process for Earphones

Our factory ensures that your earphones meet all compliance requirements with a streamlined certification process: