Earlier this week, during a video meeting with a new client, he asked a simple but important question:

“Do you have a dedicated HiFi audio testing system?

Not the standard 6151 tester — something for real acoustic development?”

Instead of explaining, I turned on my camera and walked him directly into our Acoustic Testing Room.

When he saw our B&K 4128 Artificial Head with Ears, his eyes immediately lit up.

For many engineers and brand owners, this machine is something they’ve only heard of — not many factories actually own one.

And that moment perfectly captured the difference between basic QC testing and true acoustic R&D.

At Digcue, we use both:

- B&K 4128 for HiFi-grade development

- 6151 testers for mass-production QC.

This dual system ensures that every earphone we create is both scientifically tuned and consistently manufactured.

B&K 4128 Artificial Head with Ears — The Gold Standard for Acoustic R&D

The B&K 4128 Artificial Head with Ears is one of the most advanced acoustic measurement systems in the industry.

Why it matters for high-end product development

✅ Real Human Acoustic Simulation

Replicates the human head, pinna, and ear canal — allowing engineers to measure sound exactly as a real listener hears it.

✅ High Precision for HiFi Tuning

Delivers lab-grade frequency response, distortion, leakage, and spatial audio data.

✅ Perfect for Complex Projects (Gaming, Multi-driver, ANC)

Most advanced products cannot be tuned properly without a realistic acoustic simulator.

This level of R&D equipment is rare among earphone factories — but essential for brands aiming for premium sound.

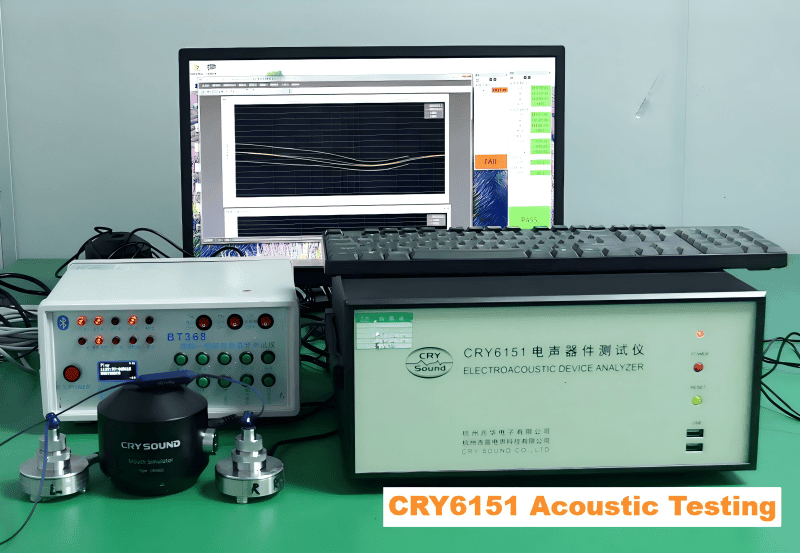

6151 Test System — Reliable, Fast, and Built for Production

While the 4128 supports R&D and sound tuning, the 6151 tester works on the frontlines of mass manufacturing.

What the 6151 is designed for

- Fast pass/fail testing

- Checking sensitivity, impedance, polarity

- Basic frequency sweeps to detect defective units

- Entirely optimized for high-volume production

It’s a crucial tool for QC, but it does not simulate human listening or provide detailed HiFi-level data.

B&K 4128 vs. 6151 — Key Differences

| Feature | B&K 4128 Artificial Head | 6151 Test System |

|---|---|---|

| Purpose | R&D, tuning, HiFi development | Production QC |

| Human Simulation | ✔ Yes | ✘ No |

| Accuracy | Very high | Medium |

| Data Type | Full acoustic analysis | Basic pass/fail |

| Suitable For | HiFi, ANC, gaming, multi-driver tuning | Mass production |

| Common in Factories? | Rare | Very common |

Why Digcue Uses Both Systems

Because great sound requires two levels of control:

1️⃣ High-Precision R&D (B&K 4128)

Ensures your prototype is tuned with professional accuracy.

2️⃣ Consistent Mass Production (CRY 6151)

Ensures every unit in every batch stays reliable and matches the approved sound signature.

By combining both, we create a complete loop from:

Acoustic design → tuning → engineering → production → QC

This is one of the reasons many brands choose Digcue for ODM/OEM development — especially for high-end or technically challenging products.

For Brands That Want Real Acoustic Performance

Whether you’re building:

- HiFi in-ear monitors

- Multi-driver TWS

- Gaming earphones with positional audio

- ANC earbuds/headphones

- Type-C wired earphones

Our dual testing system supports precise development from first sample to final shipment.

Most factories rely only on basic QC tools.

At Digcue, we make sure the sound you approve in development is the sound your customers hear in real life.

Ready to Build Better Audio Products?

We’re happy to walk you through our testing room on video anytime.

If you have a new project in mind, feel free to reach out.

📩 Email: susan@digcuetech.com

🌐 Website: www.digcuetech.com